IATF 16949:2016 is the global technical specification and quality management standard for the automotive industry. Based on ISO 9001:2015, it was published in October 2016 and replaces ISO/TS 16949. It is designed to be used in conjunction with ISO 9001:2015 and contains supplemental requirements specific to the automotive industry rather than being a standalone QMS. It specifies the requirements for establishing, implementing, maintaining and continually improving a QMS for any organization, in the automotive industry regardless of size. It brings together standards from across Europe and the US.

Everything you need to know about the IATF 16949:2016 Automotive Quality Management System

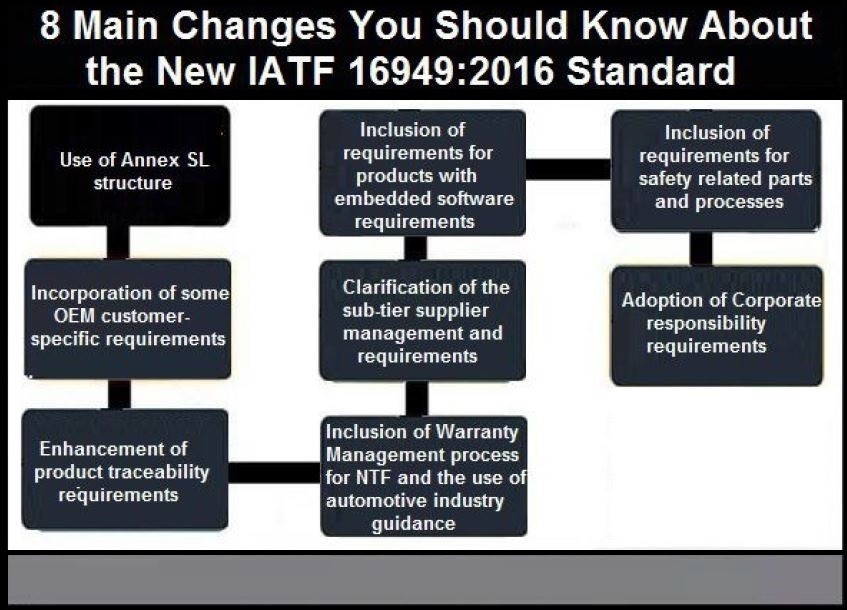

- Product safety-related requirements and considerations are added throughout the standard.

- Corporate responsibility policies such as ás ’whistleblowing’ are now required

- Risk analysis considerations are expanded beyond ISO 9001 requirements throughout the standard

- Various authorization and other requirements added related to control of nonconforming product and concessions or use of the reworked or repaired product

- Multiple requirements added throughout the standard related to managing products with embedded software

- Manufacturing feasibility requirements are enhanced to include capacity planning and the analysis is now required for any changes to processes or product designs

- Additional requirements related to an organizations supplier selection process

- Internal Auditor and Second Part Auditor competencies are more clearly defined and expanded now

- Requirement added for a second-party audit process ás part of the supplier management approach

- Statutory and regulatory conformance evidence requirement added for all materials/components for the country of manufacture and destination

- Significant expansion of the requirements related to identification and traceability or products

- Requirements added for ’Temporary change of process control’ to define and approve. in advance, alternative process controls

- Enhanced expectations related to Total Productive Maintenance

- Contingency planning requirements have been expanded

- Internal audit frequency and process coverage requirements have been modified

- Several additional inputs to be considered during management reviews

- Added requirement to have a documented process pertaining to the application of error-proofing methodologies

- The requirement to have a Warranty Management process is expected by the customers

The changes to the New IATF 16949:2016 standard implementation in your organization/quality management system will require training to processes staff etc, if you need the full Requirements of the IATF 16949:2016 standard implementation, Gap analysis, Transition from ISO/TS 16949:2009 to New IATF 16949:2016 standard, key points to bear mind in your system, process etc during Auditing process to achieve certification in your organization at an affordable cost, please contact us / call our mobile number and/or send us an email.

Thank you

You can see more of our quality management training materials that will add more to your professional experience in the below link: https://www.hermonqualitysolutions.com/training-modules-2/